QUALITY & infrastructure

Quality Comes First! We Make Sure That Every Minute Detail Is Looked Into While Manufacturing Even The Smallest Product. Our Focus Is 100% On Client Needs And Satisfaction.

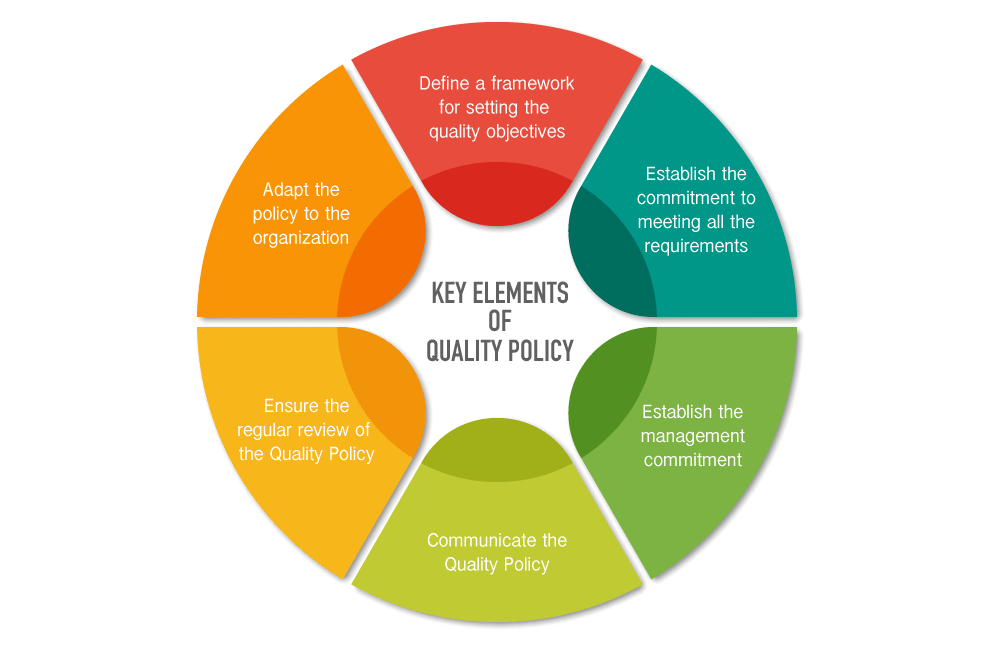

Quality Policy

PSTM, ISO 9001:2015, is in the field of manufacturing of ERW tubes, to meet the international standards, customer expectations and quality.

We are committed to follow a process approach, by encouraging interested parties, suppliers, employees of our organization to meet the customer expectations.

We shall regularly review our systems, technology, resources and results for maintaining a sustainability in our growth on continual basis.

Quality Control

The company adheres to stringent quality norms for all the processes. The materials used by PSTM are of very high quality and compatible to the latest machinery and production process. The company’s technical and commercial quality guidelines are set to high standards. A team supervises the quality assurance and control aspects along the entire process system by identifying and associating with the quality circle. Quality control tests are conducted regularly to maintain a uniform product quality.

Because We Care

Our InfraStructure

Steel Coils

We purchase high quality steel coils are purchased to meet the needs of our customers with proper thickness. These are then loaded on the uncoiler for the futher process of getting best tubes delivered to the customers as per their requirements.

Sizing & Turkhead unit

The increase of sizing stand number allows an additional reducation of final tube diameter. Turk’s heads for shaping square and rectangular tubes without changing any single roll in the sizing turk’s head stands.

Uncoiler

A material handling machine located at the beginning of a process line used to hold and safely pay off or uncoil the steel strip. It controls the speed and direction of the strip of metal as it unwinds from the coil and is sent to the line for processing, such as slitting or tube mill entry.

Cut-Off Carriage

The cutting equipment is designed for cutting tubes at high producation speed. An acutomatic control system alloows to optimize blade positioning according to the tube diameter and thickness, setting the speed of feeding and rotation of the blades. This system is able to optimise and increase number of cuts.